Triumph Over Chill: Ensuring Flawless Epoxy Grout Application in Cold Weather

Introduction

Winter's crisp bite often brings an idyllic, serene landscape, painting our surroundings with a beautiful, white canvas. However, for those working with epoxy grout, this frosty backdrop presents a formidable adversary. Cold weather doesn’t merely challenge the homely comforts but extends its icy fingers into the intricacies of construction work, notably, in the application of epoxy grout. When temperatures dip, the grout can behave unexpectedly, instigating a series of challenges that range from altering curing times to jeopardizing the final finish.

As epoxy grout is typically preferred for its durability, chemical resistance, and minimal shrinkage, ensuring its successful application in colder climates is crucial to maintaining the integrity of numerous construction projects. Tackling the rebellious nature of materials under chilly circumstances requires a blend of ingenuity, knowledge, and perhaps, a touch of winter wisdom.

Challenges Encountered During Cold Weather Grouting

- Curing Times: Epoxy grout is notorious for its fluctuating curing times in cold weather, often taking much longer to set and cure when temperatures drop.

- Consistency and Application: The low temperature can affect the viscosity of the epoxy grout, making it thicker and consequently, more difficult to apply and spread evenly.

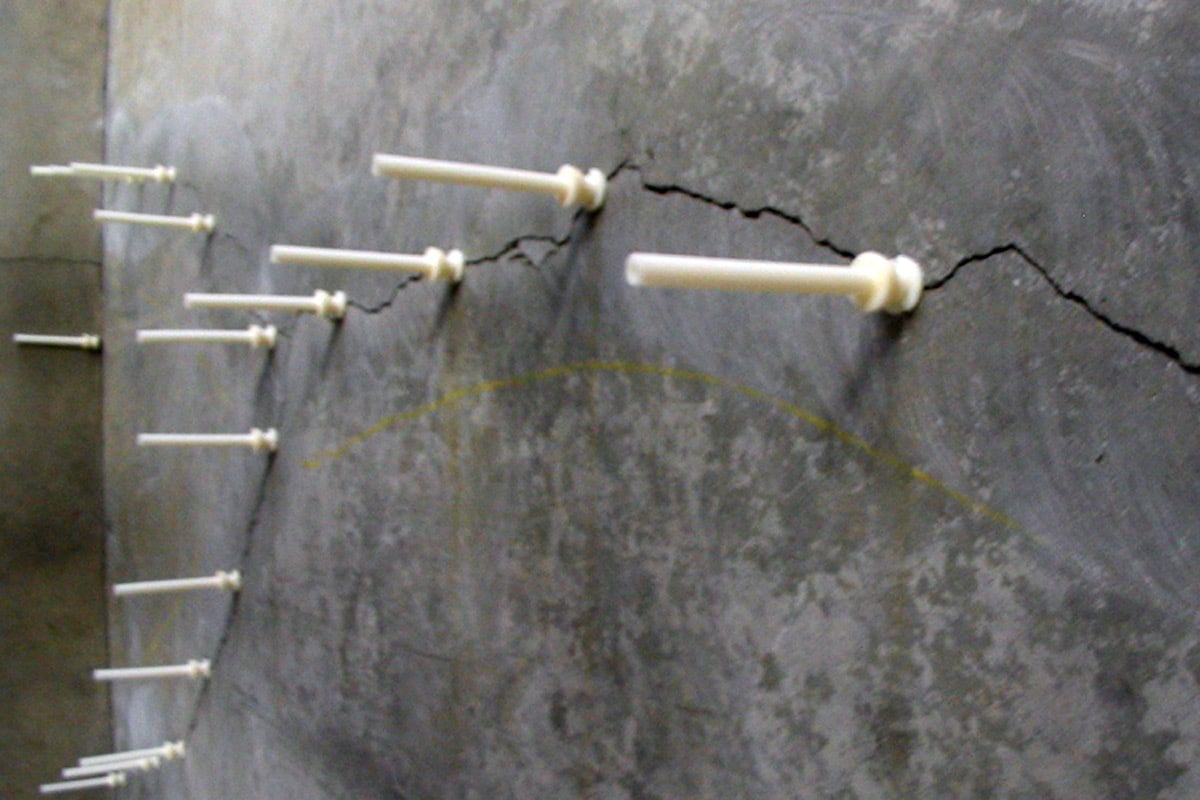

- Compromised Integrity: Cold weather may compromise the bond strength and durability of the grout, potentially leading to long-term stability issues.

- Surface Preparation: Frozen or frost-laden surfaces present adherence challenges, impacting the bond between the substrate and the epoxy grout.

Navigating the Cold: Tips and Tricks for Effective Epoxy Grout Application

- Heated Storage: Ensure that epoxy grout materials are stored in a warm environment before use. The application of cold materials can negatively impact curing times and the overall strength of the grout.

- Surface Temperature Management: Employ heating devices to raise the temperature of the surfaces to be grouted. This can be achieved through the use of portable heaters or heat lamps, ensuring the substrate is free from frost and within an acceptable temperature range for grouting.

- Monitor and Adapt to Curing Times: Be mindful that curing times may be prolonged. Always check the manufacturer’s guidelines for altered curing times under lower temperature conditions, and plan your project timeline accordingly.

- Work in Manageable Sections: Divide the work into smaller, manageable sections. This allows for a focused application and ensures that the grout does not cure prematurely before it can be adequately worked into the joints.

- Use Cold-Weather Formulas: Opt for epoxy grout formulations that are specifically designed for cold weather applications. These specialty products often feature modified curing agents that are better suited for lower temperatures.

- Protect Fresh Grout: Safeguard freshly applied grout from the elements by using protective sheets or enclosures. This will also assist in maintaining a consistent temperature during the curing process.

- Employ Expert Techniques: Utilize techniques like tenting and heating the area, which can create a microenvironment with controlled temperature conducive for grouting activities.

Conclusion

Braving the challenges that cold weather casts upon epoxy grout application necessitates an amalgamation of methodical planning, utilizing the right products, and employing clever tactics to mitigate the frigid impacts. Implementing these tips and tricks will not only safeguard your project from the icy grip of winter but also ensure a sturdy, reliable, and impeccable finish, undeterred by the cold. Winter’s chill may test the mettle of every construction professional, but with the right knowledge and approach, a seamless and robust grout application can indeed be achieved, even in the coldest of scenarios.

Please complete your information below to login.