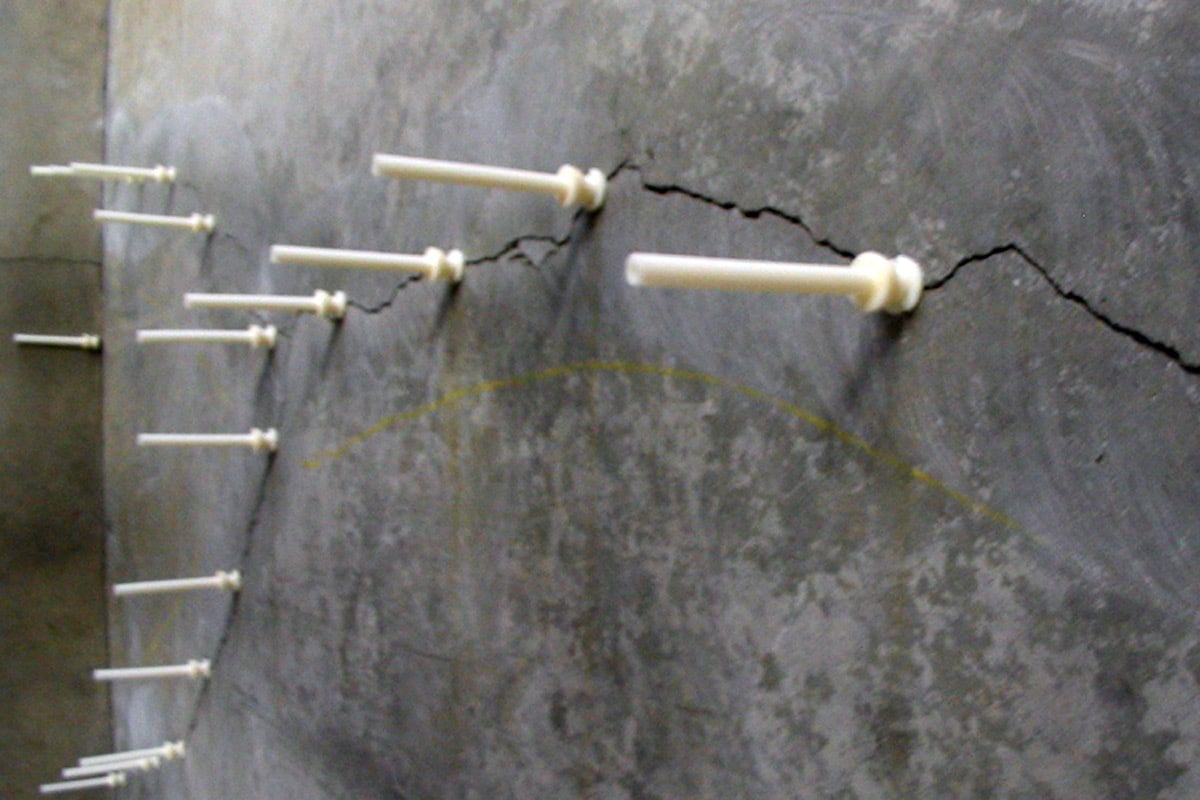

Walk in coolers, freezers, and cold storage areas are integral parts to your facility’s productivity. Just like the processing area, these areas of sub-freezing temperatures are also subject to floor damage from normal wear and tear. If these cracks, spalls, or chipped floors go unfixed, it could lead to delays in production or even create a tripping hazard. Most repair materials cannot be applied in ambient temperatures and tend to lose their shore hardness. Selecting the correct application is just as important as the actual repair. Below are a few simple rules to follow when selecting a cold storage repair material:

4 Things to Consider When Selecting the Correct Materials for Repairing Floor Joints in Cold Storage Areas

- Materials that can be applied in ambient temperatures causing them to become brittle and lose hardness.

- Let’s face it, taking an entire cooler or freezer area down to repair a crack is just not practical. The reality

Please complete your information below to login.