Concrete floors are an essential part of your plant infrastructure. Let’s face it, there’s no other real affordable option for large product storage areas. But, these large floor have to have joints to allow for stress relief and expansion/contraction to prevent cracking that could lead to eventual structural failure.

These joints have always been a weak point in the flooring system for areas of heavy traffic. However, the introduction of automated lifts and carts have pushed conventional joint design past its limits. These machines are precise. So precise that the wheels never vary from the most efficient and direct path. This shows up in wear patterns in the floor. However, the real damage is to the joint. These heavy loads are concentrated on smaller wheels that make the machine more maneuverable and unfortunately deliver more impact to the joints they cross while moving.

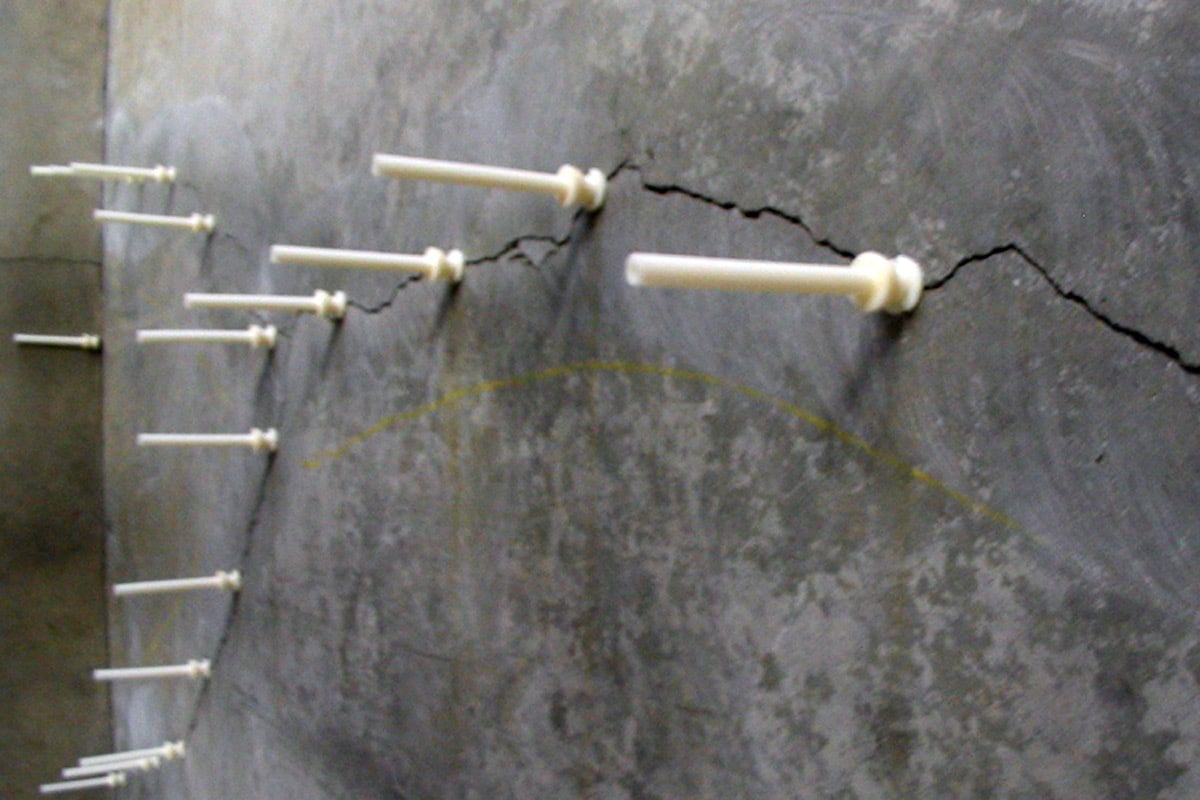

This damage creates

Please complete your information below to login.