In food and beverage facilities, one of the most important tasks is cleaning and sanitation. Trench and drain maintenance are an often overlooked – yet critical – aspect of keeping your floors clean and up to USDA standards. With the constant clean up, your trench or drain is constantly wet with water, cleaning chemicals, and waste. Unfortunately, with all that water flow, a damaged trench goes unnoticed and it may begin to leak into the surrounding soil. All of that water has to go somewhere so it runs downhill.

The leaking trench creates a void. As these voids form, it reroutes the water causing your trench to be undermined. Once this happens, your trench is vulnerable for a collapse. If a vehicle or an employee travels over the trench, not only is the trench damaged but an employee could be severely injured as well.

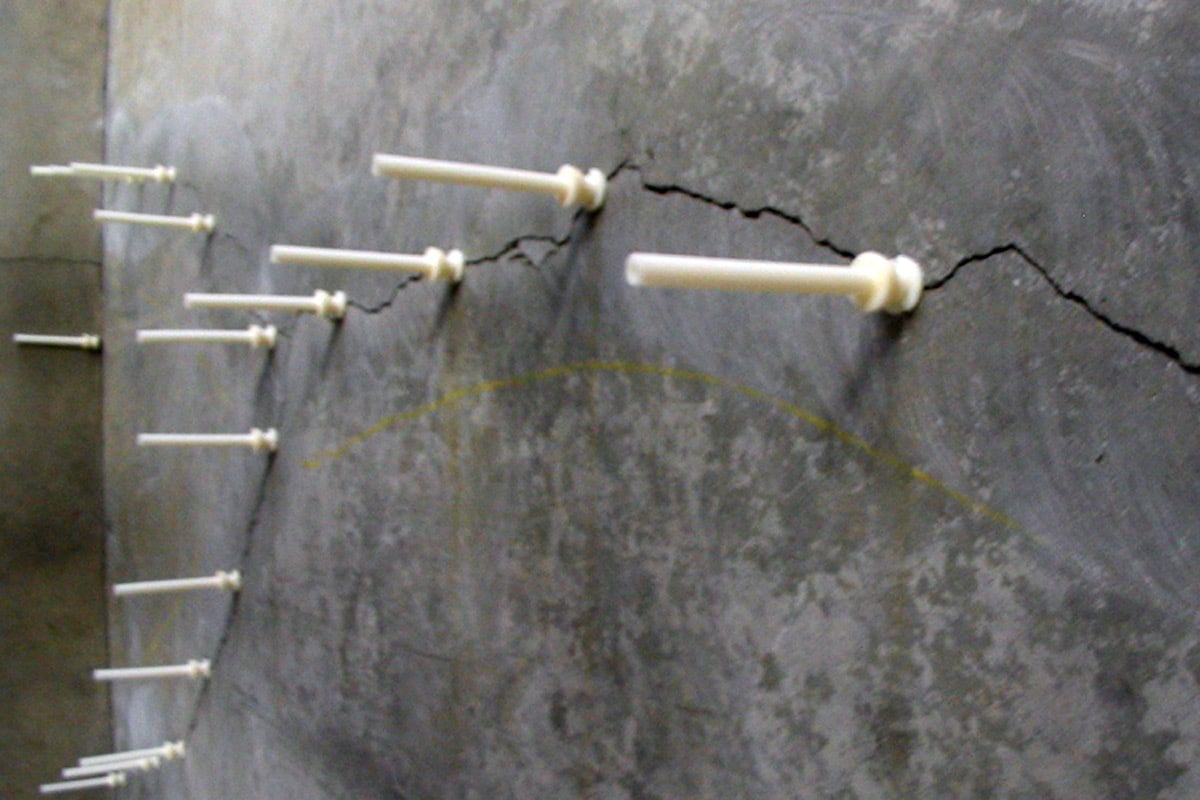

Luckily, there are materials that can stop the flow of the water outside of the trench that come in easy

Please complete your information below to login.