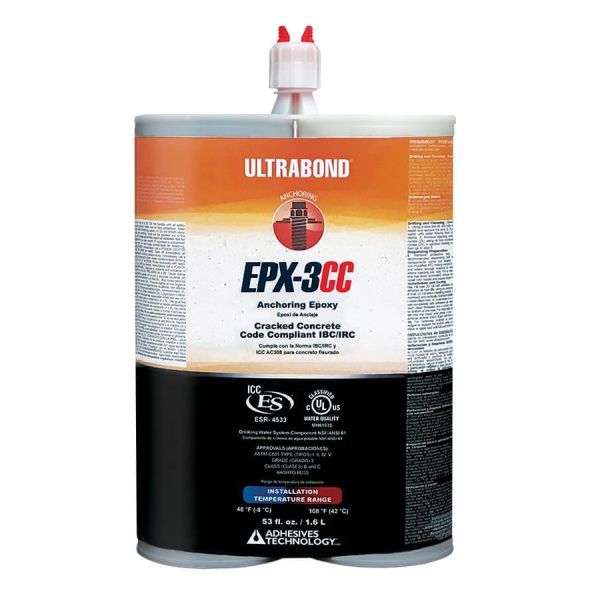

Adhesives Technology Ultrabond EPX-3CC 53oz Cartridge A53-EPX3CC

High performance epoxy anchoring system for installation of threaded rod and reinforcing bar in cracked or uncracked concrete conditions in accordance with ACI 355.4 and ICC-ES AC308.

- NSF Certified

- Vertical, Overhead, and Horizontal Applications

- Simple 1:1 Mix

ULTRABOND EPX-3CC - 53oz Cartridge

ULTRABOND EPX-3CC is a two-component, 1:1 mix ratio structural anchoring epoxy for threaded rod and reinforcing bar in cracked or uncracked concrete. It is evaluated under ICC-ES ESR-4533, meets ICC-ES AC308 and ACI 355.4, and is suitable for dry, water-saturated, and water-filled hole conditions. EPX-3CC is certified to NSF/ANSI 61 and 372 for drinking water system components. :contentReference[oaicite:1]{index=1}

Looking for another size?

Key Features

- ICC-ES ESR-4533 compliant for cracked and uncracked concrete.

- Meets ICC-ES AC308 and ACI 355.4 structural anchoring standards.

- Use in dry, water-saturated, and water-filled holes.

- NSF/ANSI 61 and 372 certifications for potable water system components.

- Approved for vertical, horizontal, inclined, and overhead anchor placements.

- Complies with AASHTO M235 / ASTM C881 Type I, II, IV and V, Grade 3, Class B and C.

- Made in the USA with broad DOT approvals.

Applications

- Anchoring threaded rod and rebar into cracked or uncracked concrete.

- Core-drilled and hammer-drilled installations across positions.

- Anchoring in damp or submerged holes with proper procedure.

- Potable water facilities requiring NSF/ANSI compliance.

- Structural applications subject to seismic and wind loading.

Technical Specifications

| Mix Ratio | 1:1 by volume. |

| Compressive Yield Strength (7 days) | 14,482 psi (99.8 MPa). :contentReference[oaicite:2]{index=2} |

| Bond Strength (Hardened to Hardened, 2 days) | 2,812 psi (19.4 MPa). :contentReference[oaicite:3]{index=3} |

| Tensile Strength (7 days) | 6,000 psi (41.4 MPa). :contentReference[oaicite:4]{index=4} |

| Heat Deflection Temperature | 135°F (57°C). :contentReference[oaicite:5]{index=5} |

| Water Absorption (24 hr) | 0.05 percent. :contentReference[oaicite:6]{index=6} |

| Application Temperature Range | 48°F to 108°F (9°C to 42°C). :contentReference[oaicite:7]{index=7} |

| Certifications | ICC-ES ESR-4533; ICC-ES AC308; ACI 355.4; AASHTO M235 / ASTM C881; NSF/ANSI 61 and 372. :contentReference[oaicite:8]{index=8} |

| Packaging | 53oz cartridge. |

Frequently Asked Questions

Is EPX-3CC code compliant for cracked concrete?

Yes. It is evaluated under ICC-ES ESR-4533 for cracked and uncracked concrete. :contentReference[oaicite:9]{index=9}

Can it be used in wet or submerged holes?

Yes. EPX-3CC is suitable for dry, water-saturated, and water-filled installations when installed per instructions. :contentReference[oaicite:10]{index=10}

Is EPX-3CC safe for potable water systems?

Yes. It is certified to NSF/ANSI 61 and 372. :contentReference[oaicite:11]{index=11}

What strengths can I expect after cure?

Compressive yield strength reaches about 14,482 psi at 7 days, with bond strength above 2,800 psi at 2 days and tensile strength about 6,000 psi at 7 days. :contentReference[oaicite:12]{index=12}

What is the mix ratio?

The system dispenses at 1:1 by volume. :contentReference[oaicite:13]{index=13}

Please complete your information below to login.