Parcel Orders over $300 Ship Free.

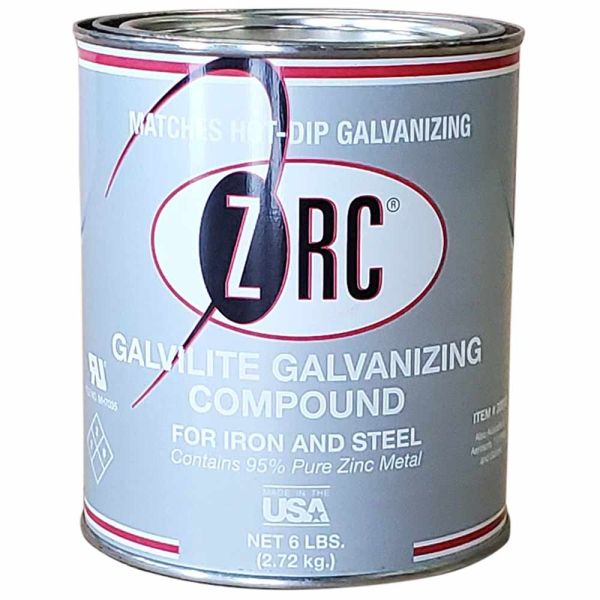

ZRC Galvilite Galvanizing Repair Compound Quart

$80.45

Availability:

Out of stock

SKU

18143

ZRC’s Galvilite provides all the corrosion protection you’ve come to expect from the world’s most specified galvanizing repair compound—in a silvery finish that closely matches the color of galvanized metal.

Benefits

95% zinc in the dry film using only Type III “ultra pure” ASTM-D-520 zinc(lead and cadmium free)

Recognized under the Component Program of Underwriters Laboratories,Inc. as equivalent to hot dip galvanizing

Meets and exceeds Fed. Spec. DOD-P-21035A (Galvanizing Repair Spec);MIL-P-26915A (USAF Zinc Dust Primer); ASTM Des. A-780 (StandardPractice for Repair of Damaged Hot-Dip Galvanized Coatings; SSPC-Paint20 (Specification for Zinc-Rich Primer)

Passes 3,000 hours salt spray testing without failure (ASTM Des. B117)

Passes 9-year subtropical testing

Low VOC approved in all 50 states

ISO 9001 registration assures the highest quality consistently

The ZRC Galvilite difference is made possible by Galvilites’s high zinc content (95% by weight in the dried film) of “ultra pure” (ASTM D 520 Type III) zinc dust, ensuring that more metallic zinc is available for superior galvanic protection against corrosion. This high purity zinc dust is compounded with a tenacious non-encapsulating binder using a highly controlled trade secret process in our state-of-the-art manufacturing facility.

The result is a self-healing galvanic film that does not require sandblasting for most applications, providing both up-front labor savings and extended longevity of corrosion protection.

See datasheet for full specifications.

Benefits

95% zinc in the dry film using only Type III “ultra pure” ASTM-D-520 zinc(lead and cadmium free)

Recognized under the Component Program of Underwriters Laboratories,Inc. as equivalent to hot dip galvanizing

Meets and exceeds Fed. Spec. DOD-P-21035A (Galvanizing Repair Spec);MIL-P-26915A (USAF Zinc Dust Primer); ASTM Des. A-780 (StandardPractice for Repair of Damaged Hot-Dip Galvanized Coatings; SSPC-Paint20 (Specification for Zinc-Rich Primer)

Passes 3,000 hours salt spray testing without failure (ASTM Des. B117)

Passes 9-year subtropical testing

Low VOC approved in all 50 states

ISO 9001 registration assures the highest quality consistently

The ZRC Galvilite difference is made possible by Galvilites’s high zinc content (95% by weight in the dried film) of “ultra pure” (ASTM D 520 Type III) zinc dust, ensuring that more metallic zinc is available for superior galvanic protection against corrosion. This high purity zinc dust is compounded with a tenacious non-encapsulating binder using a highly controlled trade secret process in our state-of-the-art manufacturing facility.

The result is a self-healing galvanic film that does not require sandblasting for most applications, providing both up-front labor savings and extended longevity of corrosion protection.

See datasheet for full specifications.

| Brand | ZRC Worldwide |

|---|---|

| Size | Quart |

| Manufacturer | ZRC Worldwide |

Please complete your information below to login.